At Chevalier Cleret Eltec, we manufacture technical silicone and rubber parts for critical sealing and damping functions in the most demanding sectors.

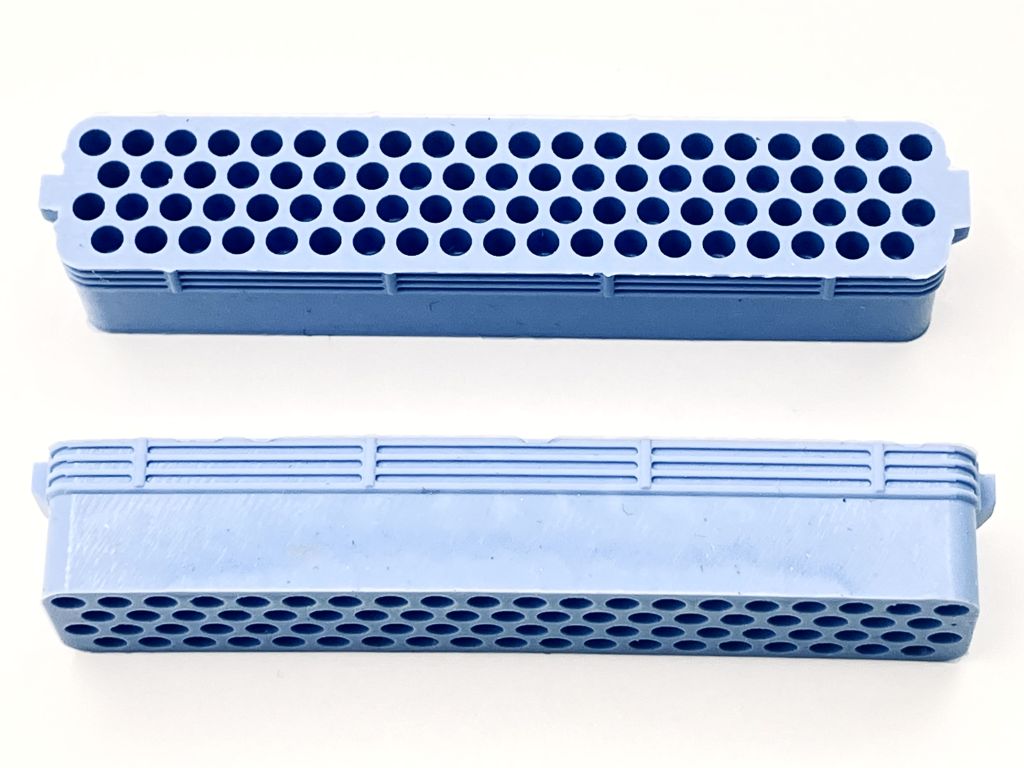

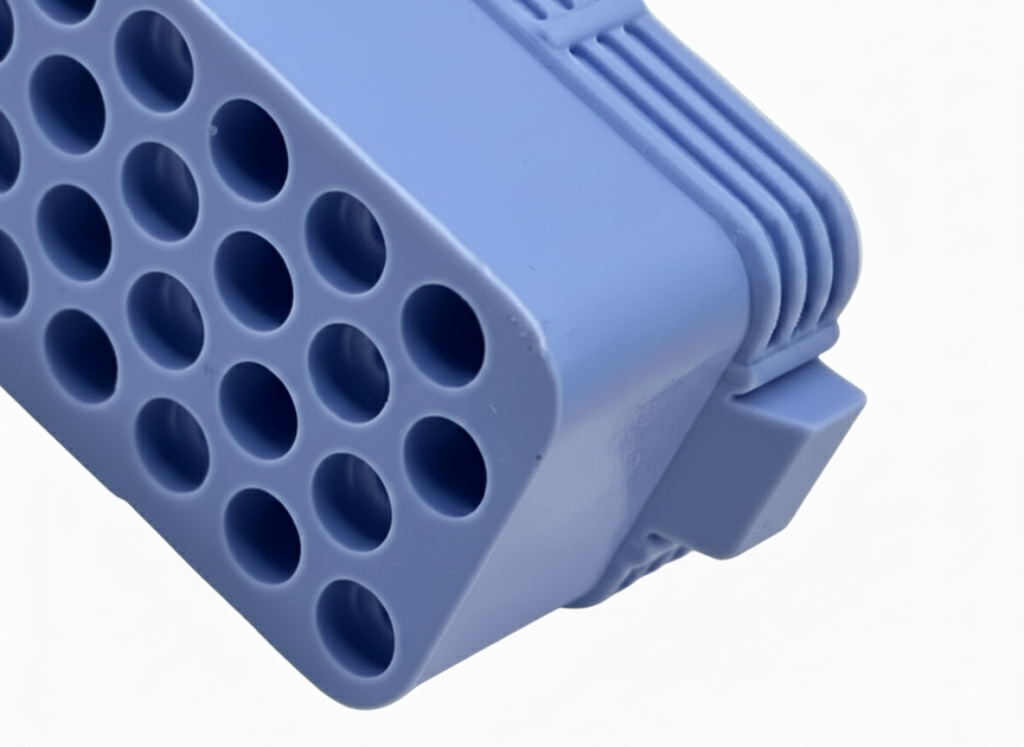

Today, we are proud to share a new development for the aerospace industry: a grommet-type elastomer part incorporating a large number of cable passages.

A complex part with very high requirements

This grommet provides a sealing function while allowing multiple bundles to pass through.

The unique feature of this part is the presence of very precise sealing lips with small diameters, requiring perfect control of both the mould AND the moulding process.

In this type of application, the final quality depends on a great many details:

- high dimensional precision

- design precautions

- very tight tolerances

The slightest variation can impact the sealing performance expected by the customer.

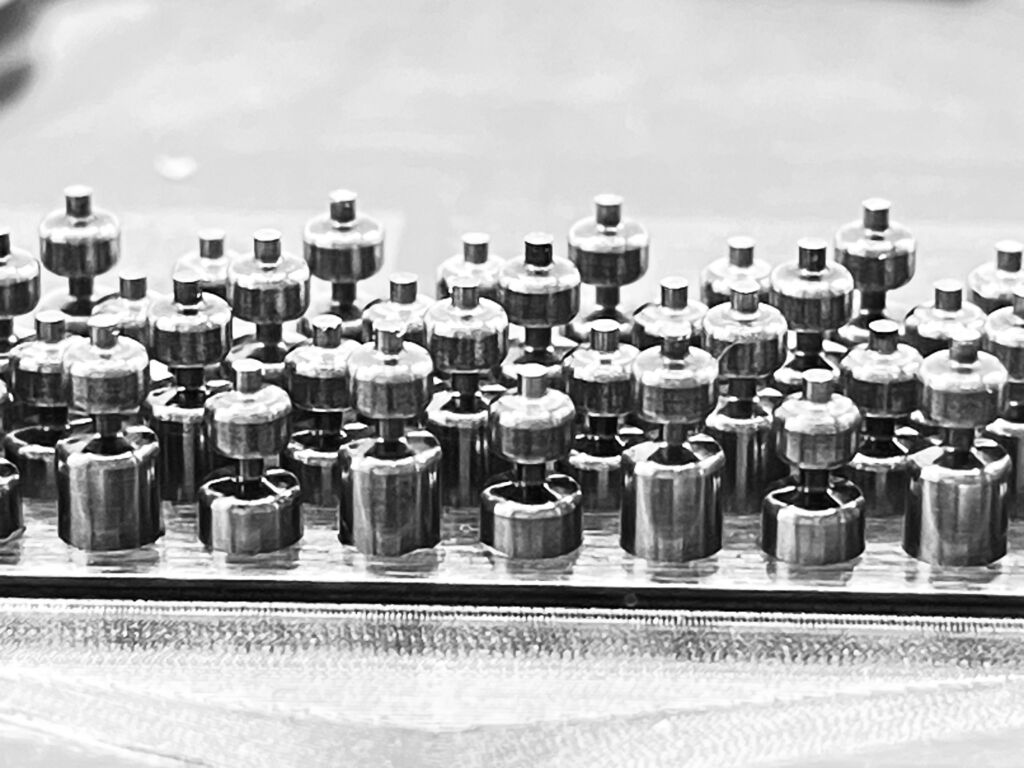

Mastery of the tools: cores and micrometric adjustments

The mould is difficult to produce because all the cores on the fixed and moving parts must touch without any misalignment, with significant pressure, in order to prevent any elastomer from seeping between the cores.

This places significant demands on:

- the flatness of the cores ends

- the concentricity of the cores

- the precision of the cores/mould adjustments

These conditions are essential for obtaining perfectly compliant parts.

Expertise developed in constant collaboration with our customer

Throughout this project, our teams worked closely and continuously with the customer: technical discussions, successive validations, design adjustments and process optimization.

This collaborative approach is at the heart of how we work: developing reliable, robust solutions that are perfectly suited to our partners’ needs.

Do you have a silicone or rubber project? Let’s talk about it.

Chevalier Cleret Eltec is available to its clients for:

- advice from the design phase onwards

- developing technical elastomer parts

- producing high-precision moulds

- producing components that meet the most stringent requirements

📩 Contact us to discuss your future silicone or rubber projects.

📎 Visit our website and immerse yourself in the world of precision moulding for the most demanding sectors.