We develop sealing, damping and fastening solutions for our customers.

We use materials that comply with the following standards: NF L 17-107, NF L 17-121, NF L 17-131, NF L 17-241 , NF L 17-250, NF L 17-260, NF L 17-261, …

Small, medium and large production runs are available, depending on the application.

The parts are 100% elastomer or hybrid elastomer/metal (or TP, glass, …)

The parts perform the following functions:

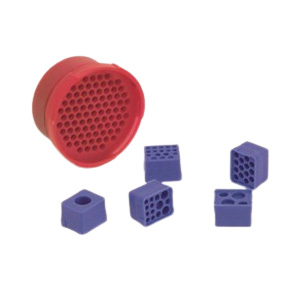

Some examples of parts

Sleeve

shock absorber

Silicone grommet

FSL overmolded membrane

Cable clamp