We are often called upon to supply silicone and rubber parts that comply with the UL94 standard, and we wanted to provide some important information on this subject.

UL94: UL 94 is the standard applied by the American Underwriters Laboratories (Underwriters Laboratories– UL was founded in 1894) to test the flammability and fire safety of plastics, silicones and rubbers used in various equipment and applications.

It determines the material’s tendency to extinguish or propagate flame once the sample has been ignited.

Flame classifications: UL 94 specifies 12 classifications, of which the following 4 are the most ‘important’:

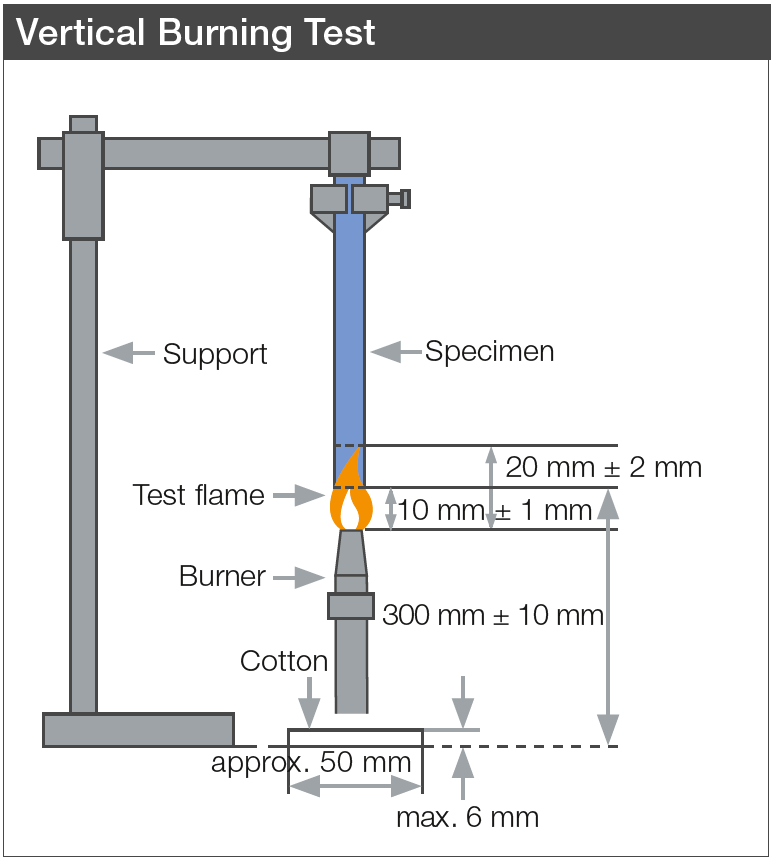

V-0 Vertical Burning: Burning stops within 10 seconds after two applications of 10 seconds each of a flame to a test sample. No ignited drops are allowed. This is the highest score for vertical burn tests.

V-1 Vertical burning: combustion stops within 60 seconds after two applications of 10 seconds each of a flame to a test sample. NO flaming drops are allowed.

V-2 Vertical burning: combustion stops within 60 seconds after 2 applications of 10 seconds each of a flame on a sample. Flame drops are authorized.

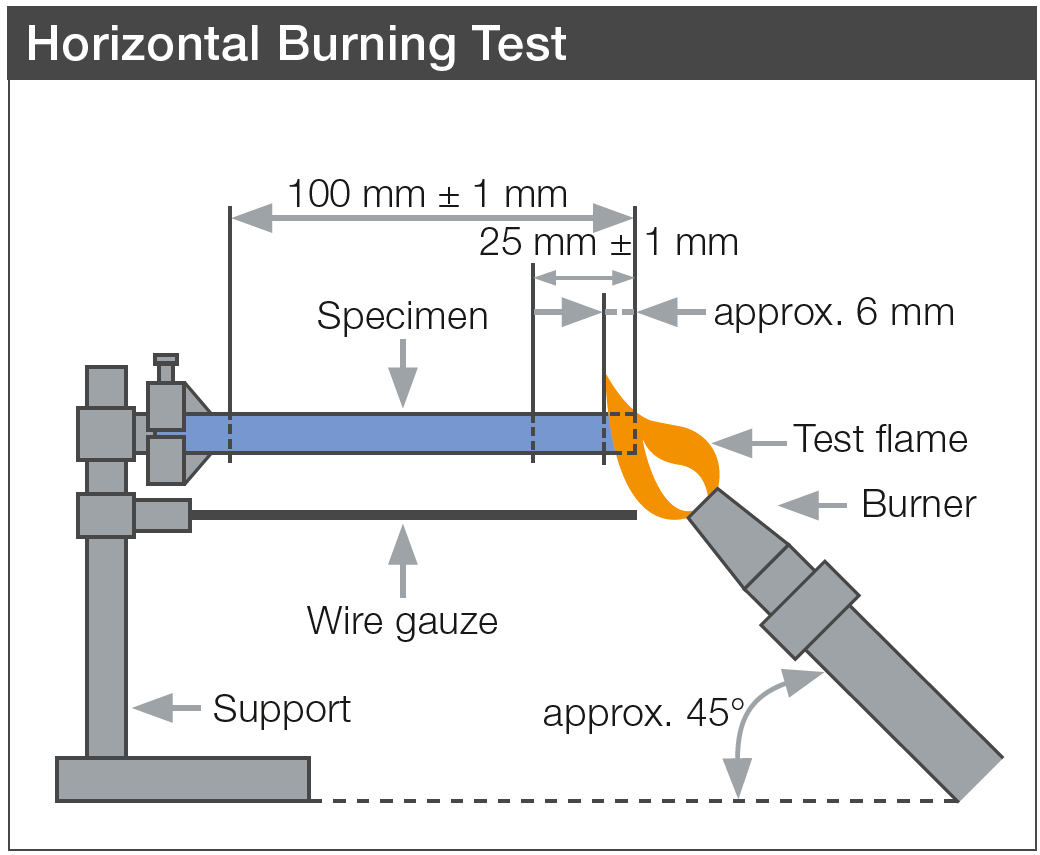

HB Horizontal burning: slow horizontal combustion on a sample with a combustion rate below a specified maximum. Materials classified as HB are considered ‘self-extinguishing’. This is the lowest UL 94 rating (the least fire retardant).

The thickness of the sample is obviously very important and must be clearly specified. This thickness must be less than or equal to the minimum thickness on the final part.

Elastomer compliance with this UL 94 standard depends on the nature of the elastomer and the formulation.

FKM generally complies with UL 94 V-0.

EPDM, in its standard formulation, does not naturally comply with UL 94 V-0 because it is generally flammable and can spread flames.

However, there are special formulations of flame retardant EPDM that incorporate specific additives (e.g. halogens, phosphates, metal hydroxides) to achieve UL 94 V-0 classification.

CR has a better natural resistance to flammability than elastomers such as EPDM or FKM. However, in its standard formulation, it does not automatically guarantee compliance with UL 94 V-0.

Some grades modified with specific additives can achieve UL 94 V-0 after certification.

NBR, in its standard formulation, does not naturally comply with UL 94 V-0. It tends to be flammable and may spread flame.

Some specific grades, modified with flame retardant additives (e.g. halogens, metal hydroxides), can achieve UL 94 V-0 after testing and certification.

As far as silicones are concerned, our suppliers offer LSR that meet this standard, and we can help you choose the right materials.

Key applications:

UL 94 is a frequent requirement in sectors such as automotive, industry and energy (solar, etc.).

Our UL 94 compliant solutions: performance and reliability

Thanks to our experience in molding silicone and rubber parts, we design customized components that comply with the strictest safety standards. We have already assisted numerous customers in the development of UL 94 compliant parts, including:

- ✔ Seals for electrical equipment

- ✔ Silicone and rubber components for aeronautics and industry

- ✔ Technical parts for electronic enclosures and systems

Some examples of UL94 compliant parts:

Sleeve – protective membrane – FKM UL94 V0

UL94 HB silicone gasket cover

Do you need a UL94-certified material or are you working on a project?

Our expertise means we can advise you on the choice of materials and processes best suited to your needs. Contact us to discuss your project and benefit from our know-how!

Contact us to discuss your project and benefit from our expertise!