Production of bipolar plates for fuel cells by process injection LSR type 3025-40 or EPDM, FKM, …

We are able to offer you proven technical solutions for overmolding elastomers

LSR or EPDM, FKM …

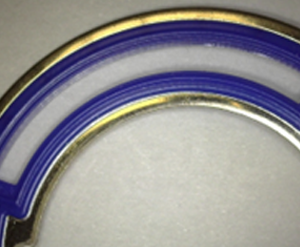

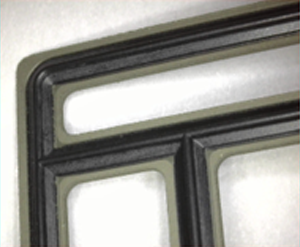

on thin metal sheets (stainless steel or other), double-sided or only single-sided

with or without adhesion

direct injection (0 loss of material) or indirect injection

in semi-automatic or full automatic process

Main features:

- Waterproofing of hydrogen, fluids and water

- Electrical insulation (with LSR)

- Resistance to pressure at high temperatures

Elastomer:

Commonly used LSR: LR 3025-40 for this type of application

EPDM, FKM, … : special formulations according to customer CDC

Details concerning the industrialization of overmoulding on insert:

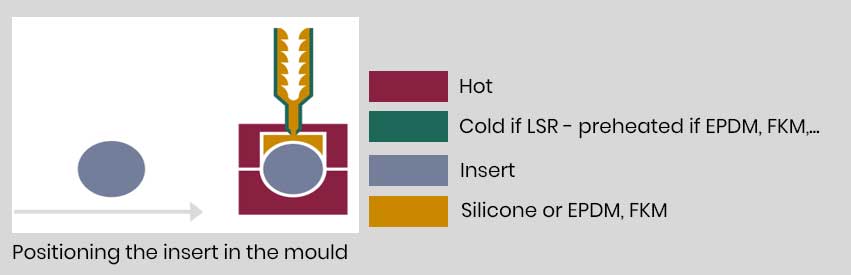

Positioning the insert in the mould

manually in semi-automatic process: site in France then site in Romania (ELTEC)

or

via robot in full automatic process

Injection molding silicone LSR or EPDM, FKM,…

MATRIX OF ADVANTAGES/ DISADVANTAGES OF OVERMOLDING VERSUS ASSEMBLY

Quality:

The +:

+ precision

+ no assembly (100% in mold)

+ no loss of function during transport or assembly

Performance:

The +:

+ reinforced by adhesion on 1 side

The –:

– recycling / end of life “complexified”

Process

The + :

+ «short» cycle time

+ stability over time

The – :

– more expensive mold

– only removes one assembly station; corresponds to the average and intermediate series

Organization

The +:

+ 1 reference only instead of 2 in management & assembly

Examples of thin metal overmoulded plates: