Technical parts in silicone and rubber for the cosmetics, medical and pharmaceutical industries

CHEVALIER CLERET ELTEC has been designing and manufacturing technical parts in silicone and rubber for devices and equipment in the medical sector for around 25 years. Our solutions are tailored to demanding environments where material purity and process control are essential.

Expertise in silicone and medical elastomer injection moulding

We master the technologies of LSR silicone injection, rubber injection, and elastomer overmoulding on inserts (plastic, metal, glass) to produce parts that meet the requirements of the medical sector.

The materials used are selected in accordance with the customer’s specifications and include

- LSR medical silicone (transparency, flexibility, sterilizable, elongation): The use of Liquid Silicone Rubber (LSR ) means that we can guarantee, through our supplies from major groups such as WACKER, ELKEM, MOMENTIVE and DOW, access to a catalogue of materials complying with a wide range of standards: biocompatible in accordance with ISO 10993, United States Pharmacopoeia (USP) class VI, European Pharmacopoeia, BfR and FDA21 Code of Federal Regulations (CFR), etc.

- Silicone HCR (high elongation, temperature resistance),

- EPDM, FKM, CR, NBR depending on specific non-patient applications.

Medical applications covered

We develop customized parts for a variety of functions:

Production under strict quality control

Our workshops in France and Romania include semi-automatic or fully automatic production lines dedicated to medical requirements:

- Controlled environment zones (clean laminar flow)

- Material traceability,

- Systematic quality control,

- Production of small, medium and large series (from prototypes to several million parts/year).

A complete offer for the medical sector

We support our customers from the co-development phase through to industrial production:

- Study of functional and regulatory requirements,

- Selection of medical silicone or technical rubber materials, injection mould design

- LSR injection moulding, rubber injection, overmoulding injection,

- Quality documentation on request (TDS, batch traceability, declaration of conformity, functional validation).

With CHEVALIER CLERET ELTEC, you benefit from proven expertise in silicone and rubber processing for precision medical applications, in compliance with the highest quality standards.

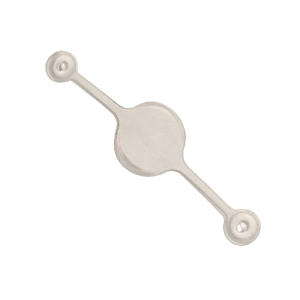

Some examples of parts

LSR nozzle

LSR cup

LSR valve

LSR elastic strap

LSR membrane