At Chevalier Cleret ELTEC, we support our automotive customers in the development and industrialisation of technical silicone parts that meet high standards.

The latest example is the development of a self-lubricating 4-way LSR grommet for a high-volume automotive application, produced by fully automatic LSR injection moulding.

🔹 A technical LSR grommet

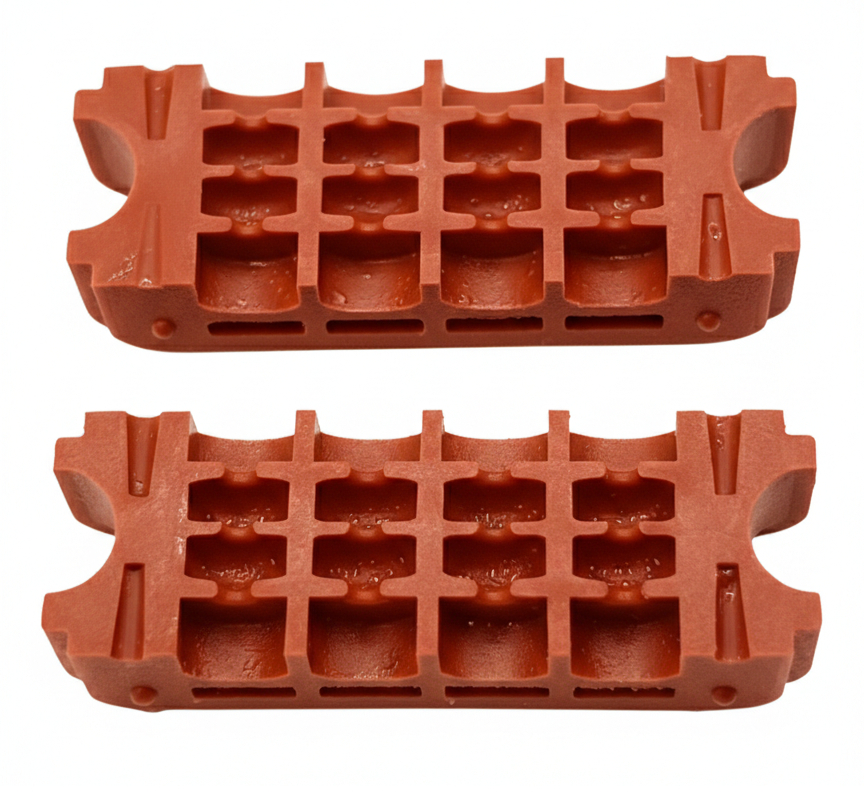

The part developed is a 4-way grommet, incorporating 3 sealing lips per contact passage, i.e. 12 sealing zones on a single part.

This requires perfect mastery of LSR injection moulding, both in terms of the geometry of the lips and dimensional stability and repeatability in mass production.

🔹 Self-lubricating LSR: principle and benefits in the automotive environment

Self-lubricating LSR is a liquid silicone that incorporates a lubricant directly into the material formulation.

This lubricant is an incompatible silicone oil that migrates to the surface of the seal after vulcanisation.

In the context of this automotive application, self-lubricating LSR offers several key advantages:

- Significant reduction in the effort required to fit contacts and harnesses

- Improved ergonomics and assembly speed for the customer

- Elimination of external lubricants (cleanliness, process control, repeatability)

Combined with a controlled LSR injection process, this type of material is perfectly suited to automotive applications.

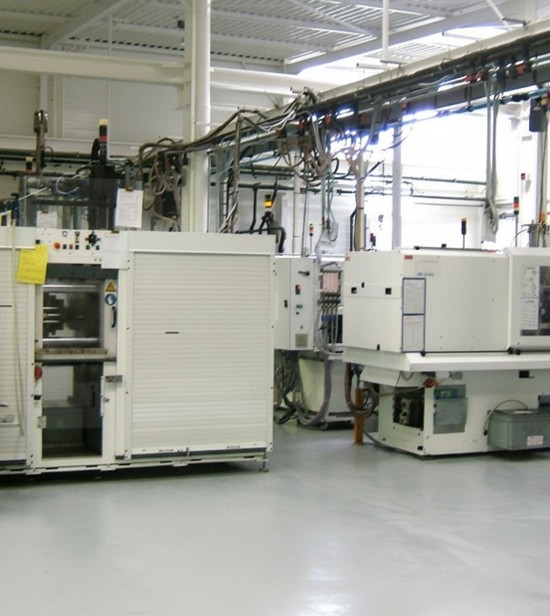

🔹 Fully automatic LSR injection for large series production

This project was industrialised using a fully automatic LSR injection process with a 36-cavity mould, enabling production volumes of several hundred thousand parts per year.

Automated LSR injection guarantees:

- High productivity

- Excellent repeatability from part to part

- Consistent quality compatible with automotive industry requirements

- Cost control in large-scale production

LSR injection

🔹 Complete development in 3.5 months

Development was carried out over a total period of 3.5 months, including:

- In-house mould design

- Mould production by approved subcontractors

- Receipt and dimensional checks of mould components

- Assembly of the various components, adjustments

- Press assembly

- Testing and determination of optimum LSR injection parameters

- Dimensional checks and creation of PPAP quality file

- Updating of technical manufacturing data

- Presentation of initial samples to the customer with PPAP file

🔹 Project management according to APQP methodology

This development was managed using the APQP (Advanced Product Quality Planning) methodology, in line with automotive industry requirements and large-scale LSR injection moulding projects.

Throughout the project, our client received continuous, structured information covering all key stages:

- validation of product needs and requirements,

- design and industrialisation of the LSR injection moulding process,

- monitoring of development milestones,

- sharing of test results and process adjustments,

- securing the ramp-up to mass production.

This organisation makes it possible to anticipate risks, ensure product and process reliability, and guarantee controlled production, adapted to volumes of several hundred thousand parts per year.

🔹 LSR injection moulding: from development to large-scale automotive production

This new development illustrates our ability to design, industrialise and produce technical silicone parts using LSR injection moulding, suitable for mass-produced automotive applications, from the design phase to fully automated production.

👉 Do you have an LSR injection moulding project involving silicone or rubber for sealing or cushioning functions?

Contact us to discuss your requirements.