Technology

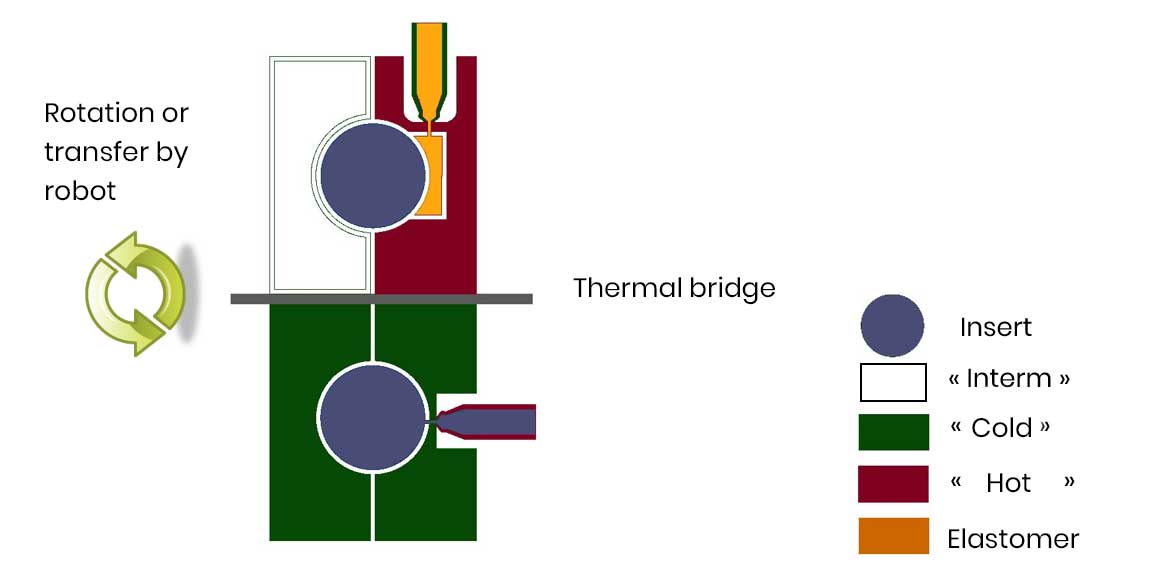

This consists of producing a hybrid, bi-material TP / LSR self-adhesive (or non-self-adhesive) assembly in a single operation on the same press.

The rigid TP part is injected via hot runners into a ‘cold’ mold, and the resulting TP part is transferred by rotation of the plate or by robot into the hot zone of the mold, where injection of the self-adhesive LSR (or not) will complete the part.

Multi-component injection molding offers designers countless possibilities. This should be taken into account right from the design phase.

Bi injection LSR/TP key ring CHEVALIER

It is also important to check the compatibility between the silicone and the substrate (metal, glass, PA, PBT, PET, …): the melting point of the substrate must be as high as possible: the physical resistance (injection pressure, adhesion) and thermal resistance of the TP part must be guaranteed.

Full details of the material combinations tested are available. Please contact us for more information.

Bi injection LSR/TP key ring CHEVALIER

It is also important to check the compatibility between the silicone and the substrate (metal, glass, PA, PBT, PET, …): the melting point of the substrate must be as high as possible: the physical resistance (injection pressure, adhesion) and thermal resistance of the TP part must be guaranteed.

Full details of the material combinations tested are available. Please contact us for more information.

The benefits of bi-injection

- No assembly required: everything is done “in mold” = 1 single process – one quality control – one item,

- High degree of automation,

- Less risk of damage during molding,

- Very stable process,

- High precision of the parts obtained,

- No need to apply an adhesion primer when using self-adhesive LSR,

- Rapid curing of the LSR,

- Easy to demold,

- No adhesion to the mold,

- Very good heat resistance up to 200°C: no melting or flowing.

- Flexibility, cold flexibility: down to -50°C,

- Chemical resistance: suitable for seals immersed in coolants, hot water, engine oils, …

- Resistance to ageing: resistant to UV, heat and X-rays

- Unlimited pigmentability,

- Less compression set than TPEs,

- Medical qualities available,

- No toxic combustion products,

- Excellent environmental compatibility,

- No plasticisers

Some examples of pieces

Chevalier key ring

Box with axle seal and peripheral seal

Valve

Some examples of pieces

Chevalier key ring

Box with axle seal and peripheral seal

Valve

Learn more about bi-injection

To learn more about bi-injection molding of self-adhesive (or non-self-adhesive) thermoplastic & LSR sub-assemblies, download our documentation. Don’t hesitate to contact us via the form if you have any questions or a project to complete.