Tensile strength and elongation at break: key properties for silicone and rubber parts

When choosing an elastomer for a technical application, two mechanical characteristics often come to the fore: tensile strength and elongation at break.

🔍 What is tensile strength (also known as maximum tensile strength)?

It’s the maximum stress recorded during the stretching of the specimen up to the breaking point. It is expressed in megapascals (MPa – 1 MPa = 1 N/mm2). The higher the value, the more resistant the material is to mechanical stress.

Tensile strength at break : this is the tensile stress recorded at the moment of rupture.

Common question: is the tensile strength at break of a rubber or silicone necessarily the maximum tensile strength?

Not necessarily

– 📈 In most cases, especially with soft rubbers, failure occurs when stress reaches its maximum: in this case, the breaking strength is also the maximum resistance.

– 🕳️ but some elastomers (stiffer, filled or highly vulcanized) may exhibit a necking zone where stress decreases slightly before rupture. In this case, maximum strength is reached before actual failure.

🔍 What about elongation at break?

This is the percentage increase in length that the specimen undergoes before breaking. A high elongation indicates a high capacity of the material to deform without breaking.

📏 How are these properties measured?

Tests are carried out on a tensile testing machine equipped with a mechanical or optical extensometer. The sample used is a standardized specimen, usually of the dumbbell 2 type, conform to ISO 37 (formerly NF T 46-002).

The speed of movement of the plate is constant (500 mm/min for specimen type 2). Force and elongation are measured as required during uninterrupted stretching of the specimen and at the moment of breakage.

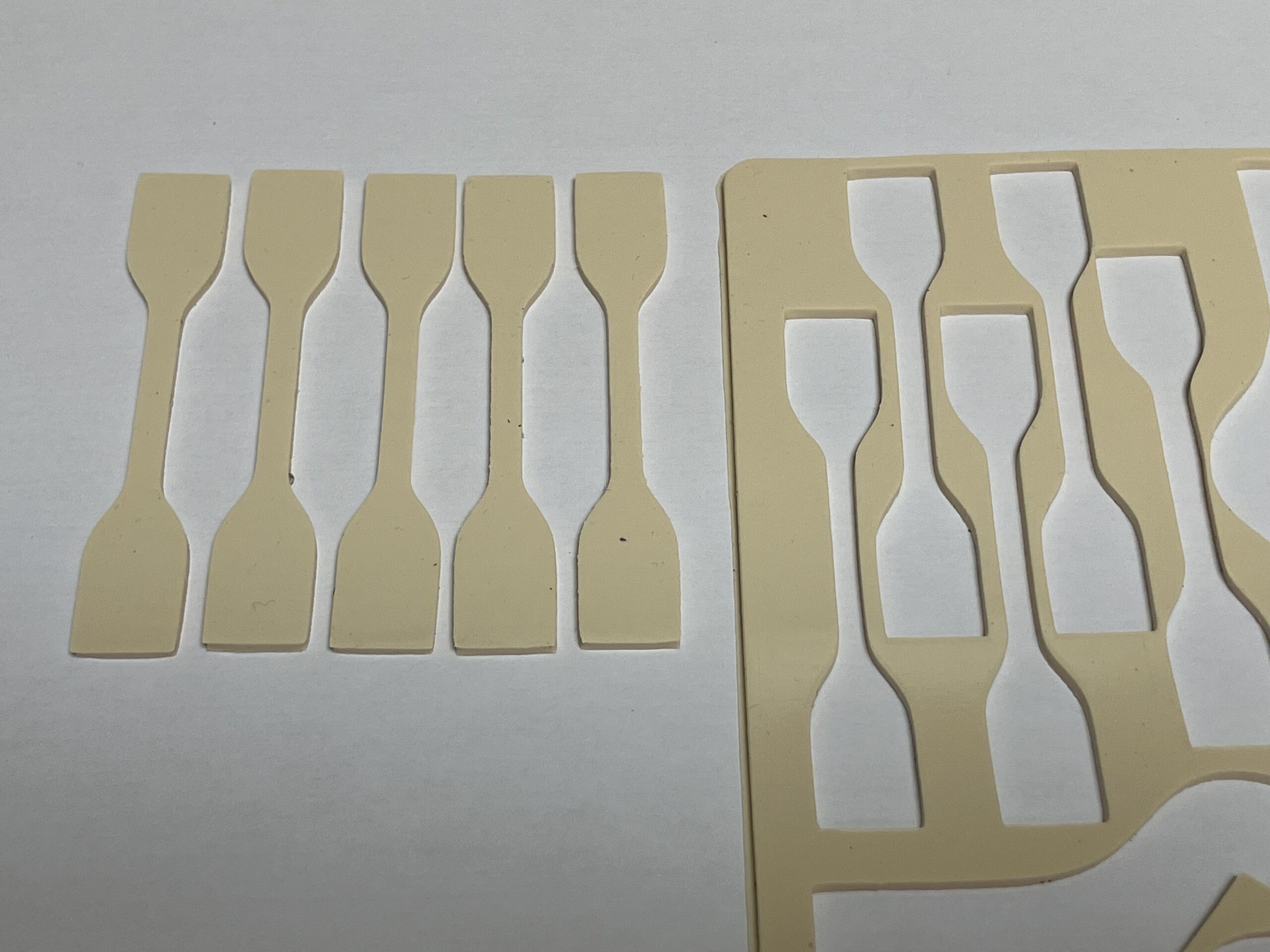

To produce type 2 test specimens, we mould plates 2 mm +/-0.2 thick with a compression process.

Then we use an ISO 23529-compliant punch to cut the specimens using a manual press.

Its central part has a rectangular cross-section measuring 4 mm x 2 mm over a length of 25 mm. Two marks, 20 mm from each other, are used to measure elongation. It is in this area that breakage normally occurs.

For all tests, the minimum time between vulcanization and the test must be 16h.

Once this time has expired, we successively place x specimens between the extensometer’s clamps for tensile testing until failure.

The equipment records and compiles the data, which we then compare with the required specifications.

Please note that the direction of calendaring of the plates to be molded and the direction of cutting of the specimens may influence the results.

⚙️ Calculation of the tensile strength, TS , expressed in megapascals, using the equation :

TS = Fm /w x t

Fm: is the maximum force recorded during the tensile test, in newtons;

w : specimen width in mm

t : specimen thickness in mm

⚙️ Calculation of the tensile strength at break, TSb, expressed in megapascals MPa, using the equation :

TSb = Fb/w x t

Fb is the recorded force at break, in newtons

⚙️ Calculation of elongation at break, Eb, expressed as a percentage, using the equation

Eb = 100 x (Lb – L0)/L0

Lb is the length of the measuring base at break, in mm

L0 is the initial length of the measurement base, in mm

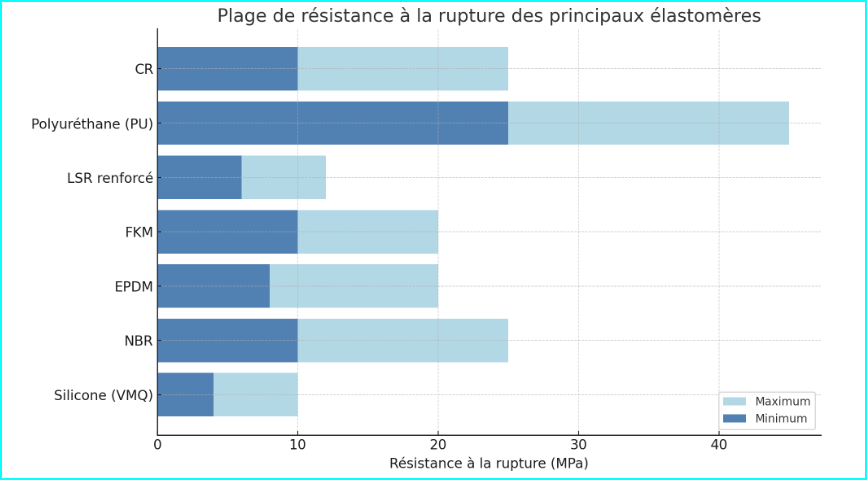

📊 Some orders of value observed in our laboratory:

These values may vary according to formulation, filler rate, level of cross-linking, any reinforcements, and type of test (temperature, speed…)

🔍 Remarks:

- Higher values are often achieved with reinforced formulations (e.g. fillers, fibers, cross-linked network optimization).

- Polyurethane is often the leader in terms of raw mechanical strength.

- Silicone and LSR, although excellent thermally and chemically, have lower mechanical strengths compared with the other families – except for specific formulations (medical, optical, high-performance).

🔍 Elongation at break according to hardness :

- 95 Shore A: 100-150

- 60-70 Shore A: 300-500

- 40 Shore A : 500-700 %

- Some special formulations achieve up to 800-1000%.

🧬 Influence of formulation

Hardness gives an initial indication, but formulation has a strong influence on this performance. Two materials with the same hardness can behave very differently depending on their molecular structure, cross-linking rate or the nature of the fillers incorporated.

🏭 Our expertise

We carry out these tests in-house to qualify our materials and support our customers in choosing the right material for their application.

🔗 Don’t hesitate to contact us for more information or a personalized study.