Principle of cylindrical grinding of elastomers

Cylindrical grinding is a finishing process that uses an abrasive wheel to smooth the external surface of a cylindrical rubber part. This process is commonly used to improve the dimensional precision and surface quality of rubber parts.

Before grinding, several steps are necessary:

- Preparation of the rubber

- Preparation of the inserts for bonding

- Elastomer overmolding on the inserts

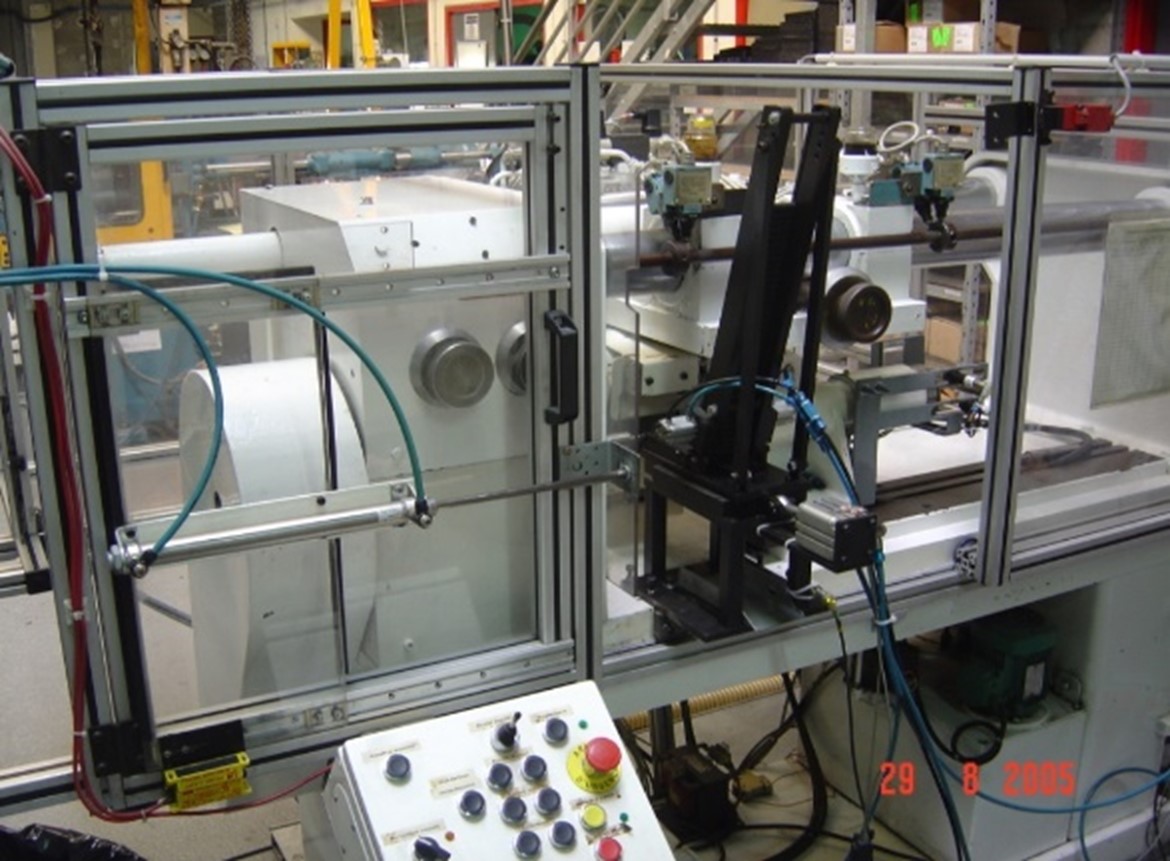

Semi-automatic grinding process

Fully automatic grinding process

Advantages of cylindrical grinding of elastomers:

Some examples of Chevalier, Cleret, Eltec products

Overmolded aluminium roller - Pu

Overmolded roller stainless steel - Silicone

Overmolded roller stainless steel – CR

Function of rollers

they are used to guide and/or print

Lean more about elastomer grinding

Don’t hesitate to contact us using the form if you have any questions or a project to complete.