Principle of die-cutting

Prepare the raw material

The first step is to prepare the rubber sheets. Either you can buy them in the format of standard sheets, or you can mold them using a mold we have of 320 x 320 mm plates.

Design the die-cutting tool

A die-cutting tool is a metal cutting tool, often made from hardened steel, designed to cut specific shapes.

Cutting process

The die-cutting tool is installed in a press. The rubber plate is positioned under the die-cutting tool. When the press is activated, the die-cutting tool is pressed against the rubber plate with sufficient force to cut the desired shape. The cutting edge of the die-cutting tools cuts cleanly through the rubber, detaching the required shape from the main plate.

Advantages of die-cutting

The elastomer die-cutting process offers several advantages over elastomer molding processes: speed, flexibility, reduced costs, simplicity of use and flexibility.

In summary, the elastomer die-cutting process offers significant advantages compared with molding, particularly in terms of speed, flexibility, investment costs, quality and simplicity of use. This method enables efficient, accurate and cost-effective production, making it the preferred choice for many industrial applications.

Function of parts: stamped parts provide sealing, damping and anti-vibration functions.

Some examples of Chevalier, Cleret and Eltec products

NBR sealing ring

NBR sealing washer

Shock absorber

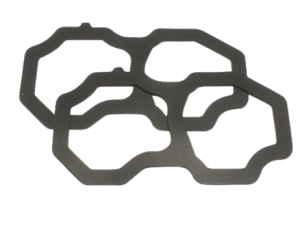

Cutting tool

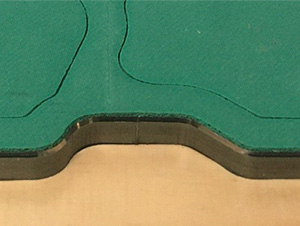

Detail of the cutting tool

Learn more about cutting elastomers

Don’t hesitate to contact us using the form if you have any questions or a project to complete.